- QUICK LINKS:

- Get A Quote

features

- draws from pre-mix solution

- powered by 120 VAC electricity

- 25 ft. (7.6 m) coiled twin-line tubing for convenient use

- 65 degree fan tip for increased coverage

- on-board compressor

- compact design

Datasheet

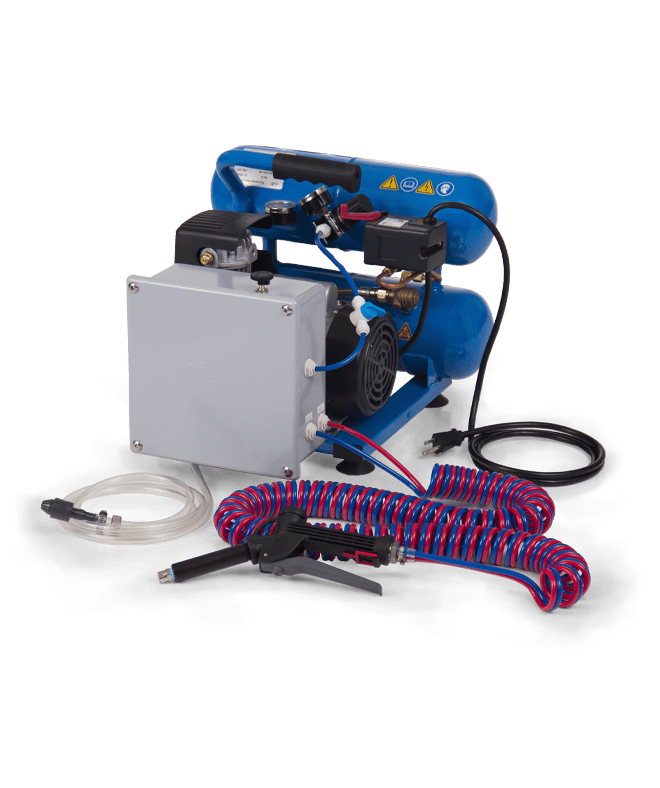

Pre-Mix Electric Foam Unit

User Manual

Pre-Mix Electric Foam Unit

Questions?

- power type

electricity

- chemical pickup type

draws from pre-mixed solution

- number of products unit can draw from

one product

- suction line length/diameter

6 ft. (1.8 m) hose with 1/4 in. (6.4 mm) inside diameter)

- discharge hose length/diameter

25 ft. (7.6 m) coiled twin-line tubing, with 1/4 in. (6.4 mm) outside diameter

- discharge wand/tip type

polypropylene trigger handle with 65˚ fan tip

- output distance

4-6 feet (1.2-1.8 m)

- output volume

6 gal/min (22.7 l/min) of foam

- flow rate*

1 gal/min (3.8 l/min)

- pump seals

Santoprene, Viton, or Kalrez

*dilution rates and flow rates given are based on chemical with viscosity of water and factory air pressure settings.

- liquid temperature range

40-100˚F (4.4-37˚C)

- electrical requirements

120 VAC at 60 Hz, 10 amps (GFCI protected outlet)

- operating voltage

120 VAC

- chemical compatibility

Chemical products used with this equipment must be formulated for this type of application and compatible with unit materials and pump seals. For more information on chemical compatibility, consult the manufacturer or SDS for your product or contact our customer service department.

- complete unit with discharge hose and wand

- user manual

Support Videos

FAQs

Which pump seal material should I choose?

Pump Seal Material Compatibility

Choose a pump seal material that is compatible with the chemicals you will use. Chemical incompatibility can cause accelerated wear and equipment failure that is not covered by warranty, so it’s important to do your research.

- Consult the safety data sheet (SDS) for your chemical to learn about the ingredients.

- Use a chemical compatibility database (like this one: https://www.coleparmer.com/Chemical-Resistance) to look up the ingredients and find material compatibility info.

- Note that the concentration of chemicals makes a big difference in compatibility. Think about whether the chemical you use will be in a pre-diluted or concentrated form when it is used in the equipment.

- If you need help, ask your chemical manufacturer. Or, send your SDS to techsupport@foamit.com and we can help.

How to Buy?

We have distributors all over the world. Tell us a little bit about you and your equipment needs, and we’ll help you find or become a distributor.