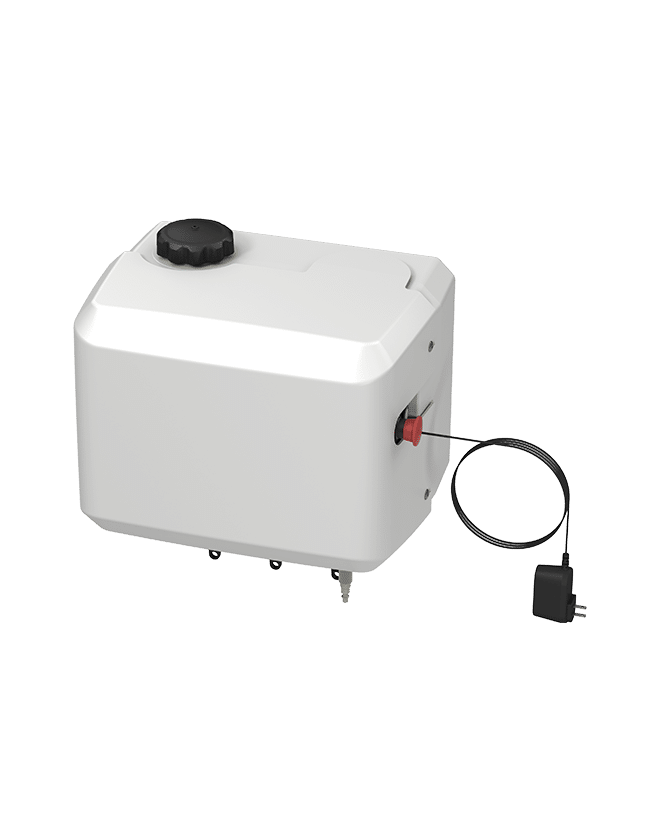

Flooded Suction Tank

#FSTProvides consistent head pressure for metering pumps, eliminating the loss of prime and ensures dosing accuracy. Multi-level switch monitors high and low levels of chemistry, alerting users when attention is required.

Provides consistent head pressure for metering pumps, eliminating the loss of prime and ensures dosing accuracy. Multi-level switch monitors high and low levels of chemistry, alerting users when attention is required.

compressed air and electricity

24 VDC; power supply included

8A 250VAC / 8A 30VDC

draws from concentrated, pre-mixed, or ready-to-use product

one product

3.5 gallons (13.2 liters)

up to 2.5 gal/min (9.5 l/min)

polypropylene ball valve with Viton seals

Santoprene, Viton, Kalrez

EPDM, Viton, Teflon

60-80 psi (4.1-5.5 bar) with 5-10 CFM (141.6-283.2 l/min)

100-240 VAC at 50-60 Hz, 1 amp (GFCI protected outlet)

40-100˚F (4.4-37.8˚C)

Chemical products used with this equipment must be formulated for this type of application and compatible with unit materials and pump seals. For more information on chemical compatibility, consult the manufacturer or SDS for your product or contact our customer service department.

| Product | Pump Seal Material | Valve Seal Material |

|---|---|---|

| FST-E | Santoprene | EPDM |

| FST-V | Viton | Viton |

| FSTK-T | Kalrez | PTFE |

We have distributors all over the world. Tell us a little bit about you and your equipment needs, and we’ll help you find or become a distributor.

We can’t clean your inbox, but we can help keep it interesting. Stay in the know on products, improvements, and other news.